Who We Are

The Working Group for Cage Processing

The Working Group Cage Processing (AK KAB) was established in Germany in 2005. Since its foundation, the members have been committed to the creation and publication of expertise on the safe and value-preserving processing of animal housing systems used in biomedical research.

Already in 2006, the world's first publication of the so-called "Orange Brochure", "Cage processing in Animal Facilities properly done", was published at the GV-SOLAS conference in Freiburg.

Our Mission

The aim is to provide a manufacturer-neutral guideline for planning, procuring and operating processing systems and single processing components, and thus wish to address planners, manufacturers, and operators alike.

To this end, experts from various disciplines, such as veterinarians, biologists, mechanical engineers, product managers, hygienists and business people work closely together in a trusting relationship that transcends departmental and company boundaries.

Our Aim

Development and publication of recommendations for the automated processing of reusable processing goods, based on practical experience for practical use, focussing on ergonomic, sustainable and economical work processes and retaining the value of the goods.

The focus is on user-related information and recommendations on the following key points:

- cage processing cycles

- Requirements of items for processing

- Cage processing procedure

- Constructional requirements

- Operation and operating

- Performance evaluation checks for washing systems

- Ecological requirements

- Potential defects and material damages

In the 2nd edition 2008, the AK KAB already added the reduction of microorganisms of heat-sensitive items by means of hydrogen peroxide (H2O2)/peracetic acid (PAA) and the performance evaluation checks for washing systems.

A complete revision and update was carried out in 2013 for the 4th edition, with particular attention being paid to problems in the processing of feeding bottles. In the 5th edition 2016, the process steps for cage processing were essentially adapted to the state of the art. The special requirements for process validation during sterilisation were also added. In the 6th edition in 2020, further developments in chamber dimensions for sterilisers and H2O2 material locks were updated. Furthermore, additional information for periodic checks of sterilisation and cleaning results to ensure the system functions in accordance with the recommendations of the AK KAB as well as possible inspections and evaluations of the processes of cleaning systems according to certain sustainability criteria have been included.

The international relevance of the AK KAB brochures is reflected in the fact that they have been published in English since 2010 and are equally appreciated in many countries.

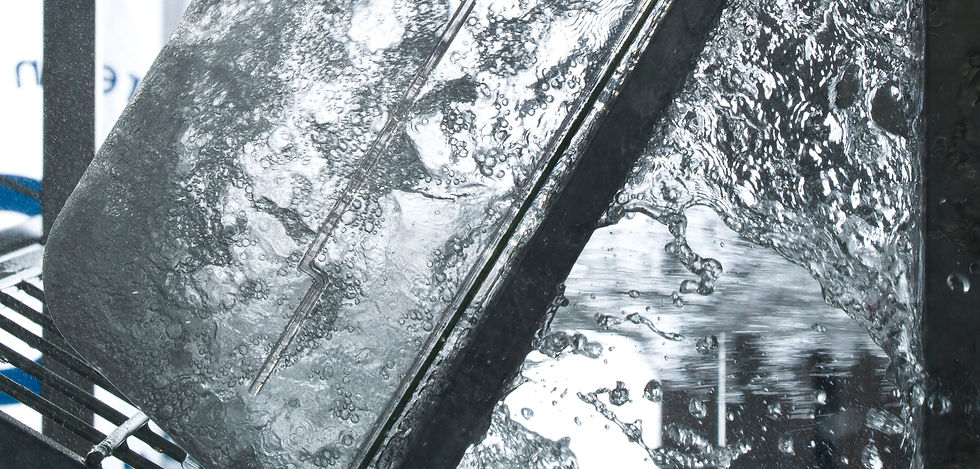

In the meantime, the Working Group Cage Processing has also been working on the processing of aquatic housing systems. As the requirements and the resulting recommendations differ considerably from cage processing, these have been published in a separate booklet of the Working Group Cage Processing entitled "Fish Tank Processing in Animal Facilties” in the 1st edition 2020.

The working group sees it as its very own task to keep these brochures up to date with the latest technology and the experience gained from the user sector in the form of updated editions in the future and to impart this knowledge to interested parties through lectures and workshops.